Equipment parameters

| Project | Parameter |

| Laser | JPT 100W nanosecond customization |

| work area | 800*800mm/1300*2500mm/1500*3000mm/2400*3600mm |

| scanning speed | 12000mm/s |

| wavelength | 1080nm |

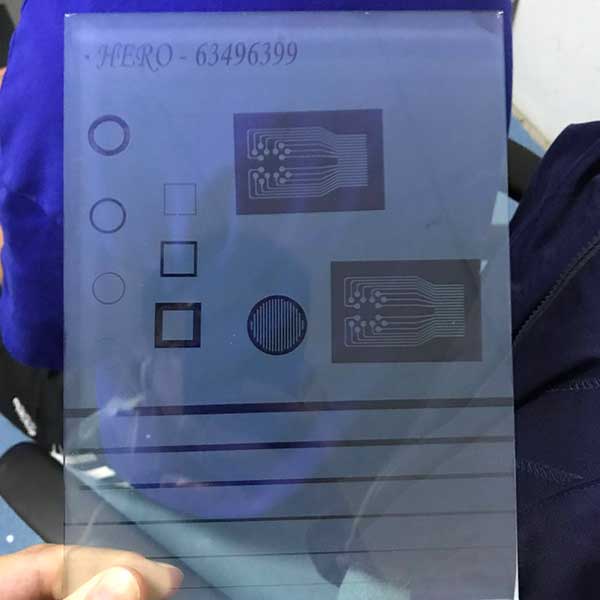

| First line width | 0.012mm |

| Minimum character | 0.15mm |

| Repeatability | ±0.03mm |

| Movement System | 5-axis linkage |

| Electrical system | Schneider, France |

| Voltage | 220V/380V |

| Control card | LIKE LASER German Customization |

| Refrigeration Method | water-cooling |

| Weight | 1200kg |

| Picture Format | BMP,PLT,AI,DXF,DST etc.Vector format |

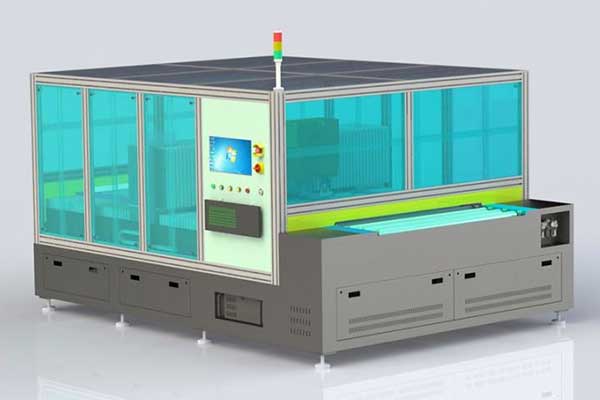

DESCRIPTION

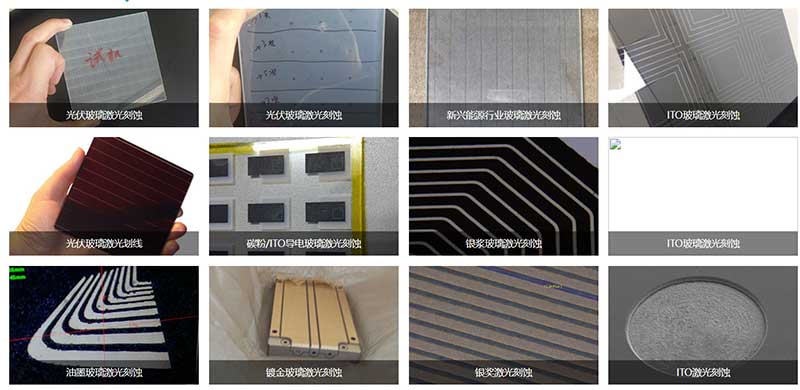

Glass laser film removal machine is a device specifically designed to remove glass surface coatings, which uses laser technology to perform precise film removal treatment on the glass surface. This type of equipment is commonly used in fields such as glass manufacturing, building decoration, and the automotive industry

Working principle

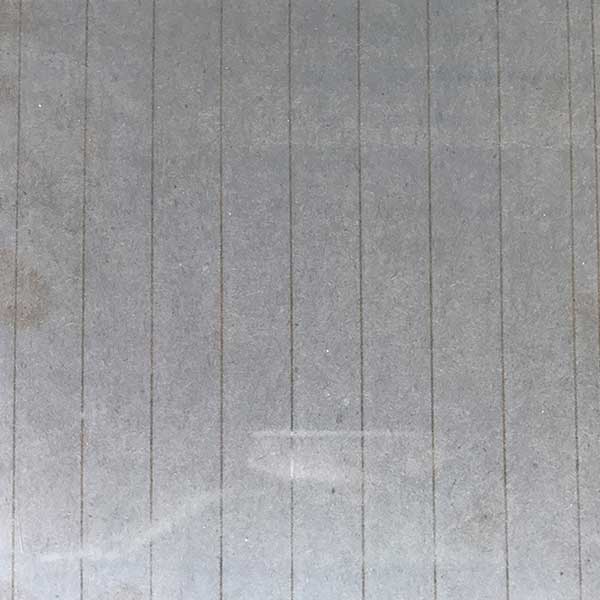

The glass laser film removal machine uses a laser beam to remove the coating on the glass surface. The high energy density of the laser beam can cause the coating to evaporate or melt under heat in an extremely short period of time, thereby achieving the goal of removing the coating

Automatic control system

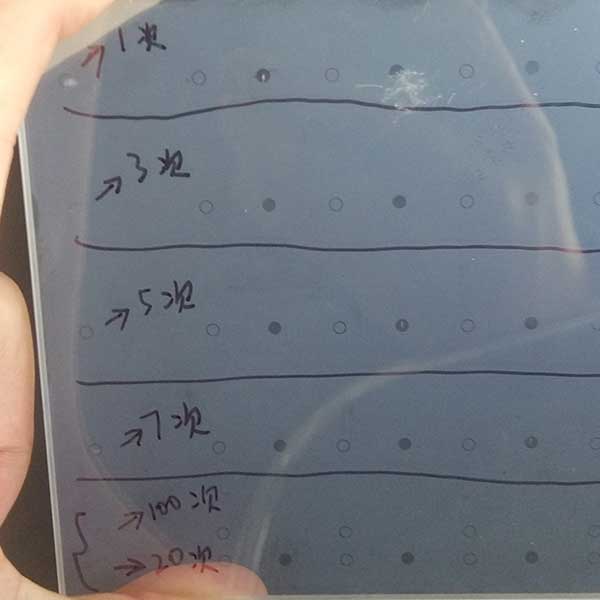

Equipped with an automated control system, precise settings and adjustments can be made based on glass size and coating requirements. Users can input parameters such as film removal area, speed, and power through the interface or software

High efficiency and accuracy

The glass laser film removal machine has the characteristics of high efficiency and accuracy. It can quickly and evenly remove the coating without causing damage to the glass surface during operation.

YouTube Display

Carve