DESCRIPTION

Laser drilling is the process in which a laser is focused and used as a high-strength heat source to heat a material, causing it to melt or vaporize within the laser action zone, thereby evaporating the highly concentrated laser beam in space and time. It can reduce the diameter of the spot to micrometers and achieve high power density, making it possible to drill almost any material with laser drilling. The most prominent feature of glass laser drilling is that it uses non-contact drilling, which means there is no need for molds, no trouble with wear, repair, or replacement, and the automated drilling speed is fast and efficient, 10 to 100 times faster than traditional drilling speed. It can drill holes on various inclined surfaces, and the processed workpiece is smooth and burr free, without the need for secondary processing, with high economic benefits.

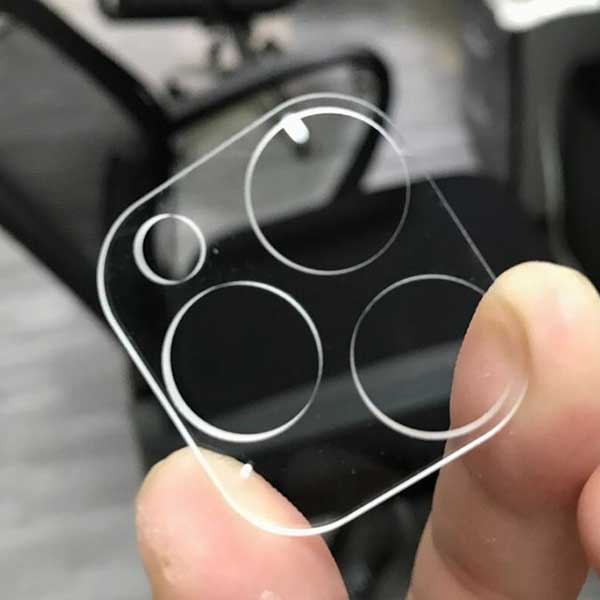

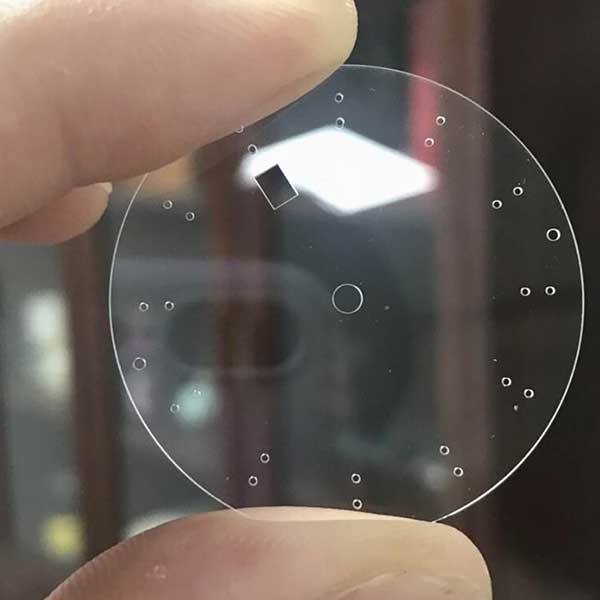

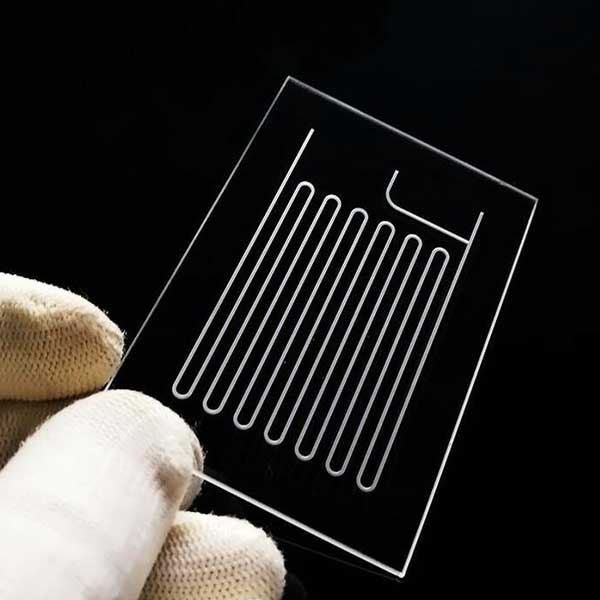

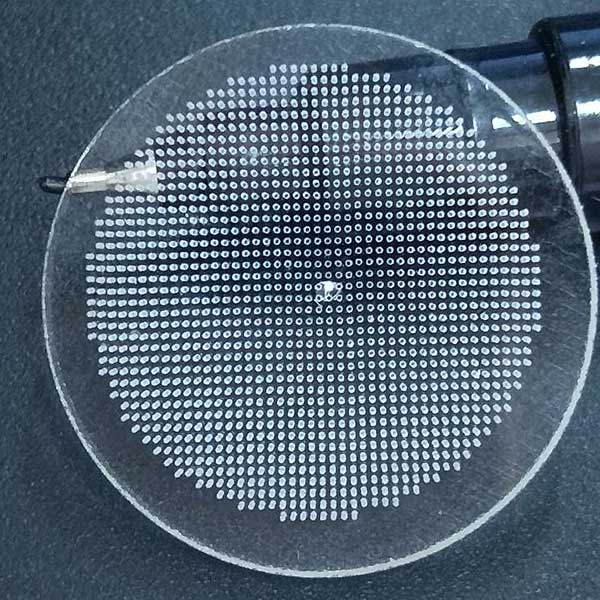

Multiple shapes

Compared to traditional glass drilling machines, laser technology is used to carve holes in various shapes such as circular, square, and polygonal to meet different needs

No consumables required

Laser drilling without consumables Traditional cutting requires regular replacement of the cutting head

Smaller heat affected area

Laser cutting 10um, traditional knife cutting has hard force damage

Perforated edges are better

Laser cutting does not require edge grinding traditional knife cutting requires edge grinding

Equipment parameters

| 设备名称 | 绿光纳秒光钻孔机 | 红外亚纳秒光玻瑞钻孔机 | 红外mopa激光钻孔机 |

| Equipment model | LK-GNC-6070/8010 | LK-INC-6070/8010 | LK-MNC-6070/8010 |

| Laser type | Green light pulse | Red light sub nanosecond | Mopa nanosecond laser |

| laser power | 10W/30W/45W | 50W/70W | 100W |

| wave length | 532nm | 1064nm | 1064nm |

| Pulse velocity | 7ns@100KHz | 8ns@100KHz | 6-100ns |

| pulse power | 50-500KHz | 50-500KHz | 1-4000KHz |

| Refrigeration method | water-cooling | water-cooling | water-cooling |

| Cutting method | Electrically controlled Z-axis+2D galvanometer/2.5D galvanometer | ||

| cutting head | Scanning field mirror+telecentric lens | ||

| Drilling width | <Q100mm | ||

| Cutting speed | 0-6000mm/s adjustable | ||

| Cutting thickness | <20mm | ||

| Collapse range | 30-200um | 150-300um | 250-450um |

| Cutting platform format | 600x700mm800x1000mm|可定制 | ||

| Drive motor | Linear motor | servo motor | servo motor |

| positioning accuracy | 3um/+5um | 5um | 5um |

| software performance | Support cutting data formats: dxf, dwg | ||

| Dust removal system | High negative pressure smoke and dust machine | ||

| Power specifications | AC220V+5%,L+N+E<3KW | ||

| Power specifications | 1560mmx1750mmx1750mm/1900mmx1800mmx1900mm | ||

| Equipment weight | <1500KG | ||

| Ground bearing capacity | >500kg/m2 | ||

| advantage | Fast speed, high accuracy, good stability, non-contact processing, and high yield. The minimum diameter of the processing aperture is 0.1mm, and it can process any shape such as square holes, circular holes, step holes, etc |

Integrated and compact design, easy to integrate excellent spot quality M2<12, available in three wavelengths: infrared, green, and ultraviolet. The highest power in the green light band exceeds 40W, with a repetition rate of 50KHz-5MHz. Pulse width of 0.1ns~500ns is optional |

The characteristics of stronger pulse energy and higher peak power Compared to picosecond lasers, the price is more affordable |

YouTube Display